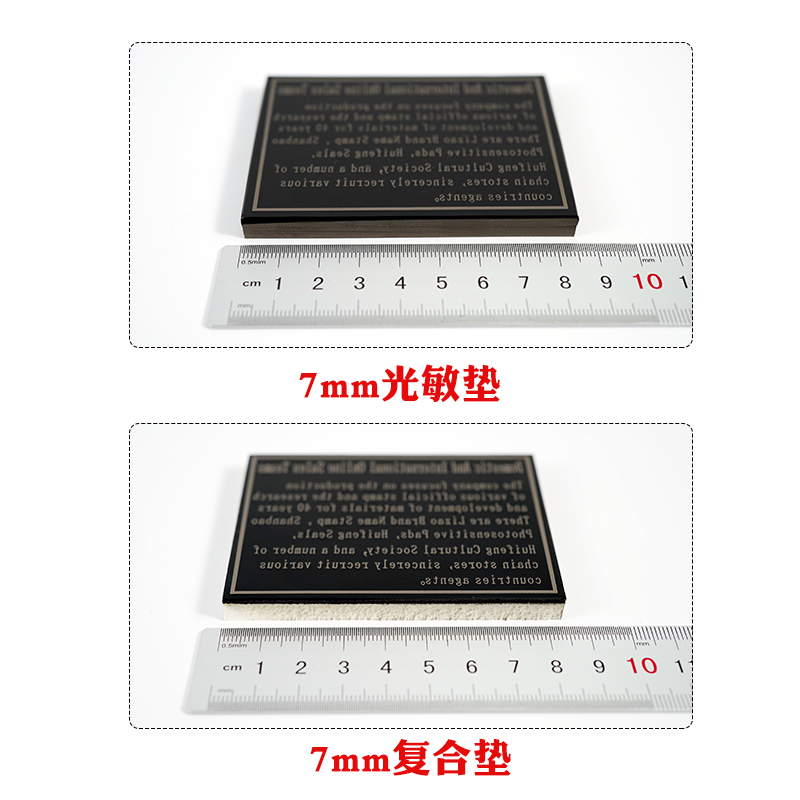

1. Photosensitive seal conventional photosensitive pad material

Thickness specification: 1.5-7mm

2. New material for photosensitive seal composite pad

Thickness specification: 3-7mm

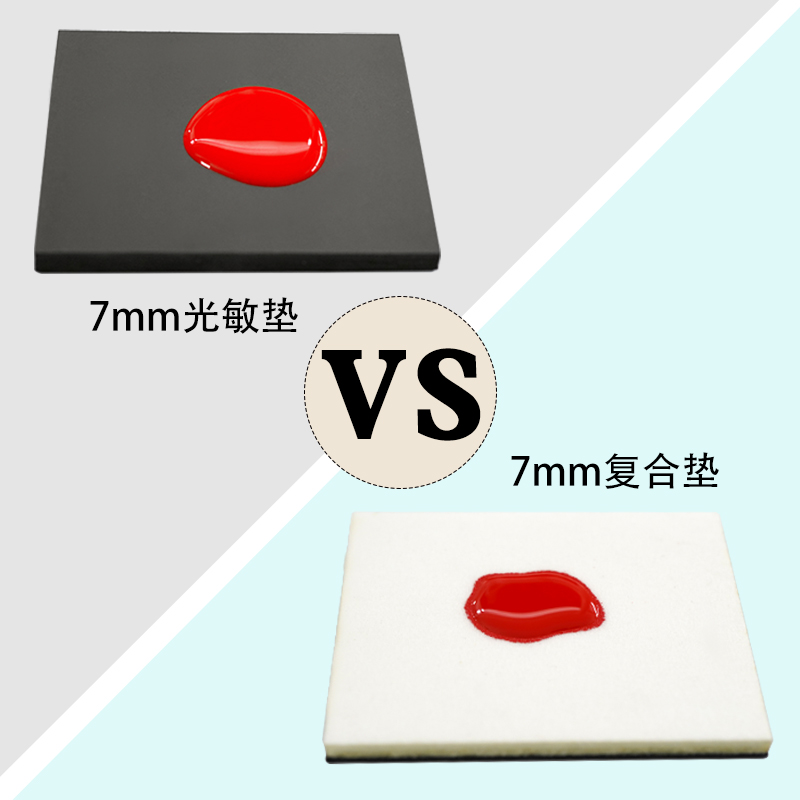

7mm photosensitive pad

VS

7mm composite pad

VS

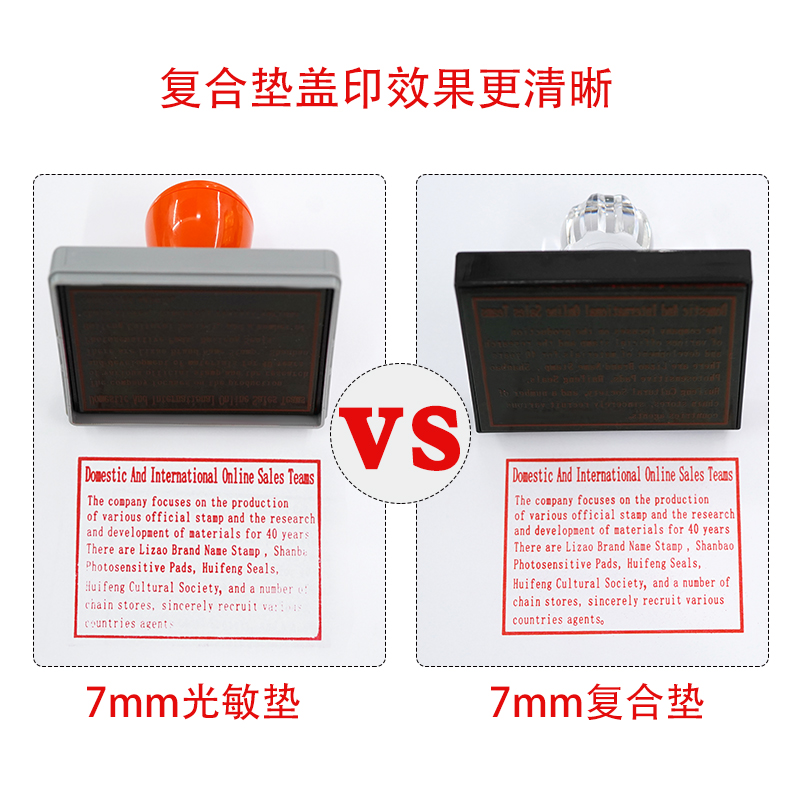

7mm photosensitive pad-stamping

VS

7mm composite pad-seal

Continue ink

clarity

Continuous stamping

1. Number of stamping A photosensitive pad: 4000 times B composite pad: 15000 times

2. Ink refill A photosensitive pad: slow ink refill, even slower after 3 ink refills, less oil storage B composite pad: fast ink refill, unlimited ink refill times, more oil storage

3. Stamping effect.

A photosensitive pad: the clarity gradually fades, and it is laborious to press continuously for stamping. B Composite pad: the clarity is long-lasting, and it is labor-saving to press continuously for stamping.

Post time: May-17-2024